- Length: 600mm / 24inch

- Height: 200mm / 8inch

- Thickness: 100mm/4 inch

- Product Code: 4 inch

-

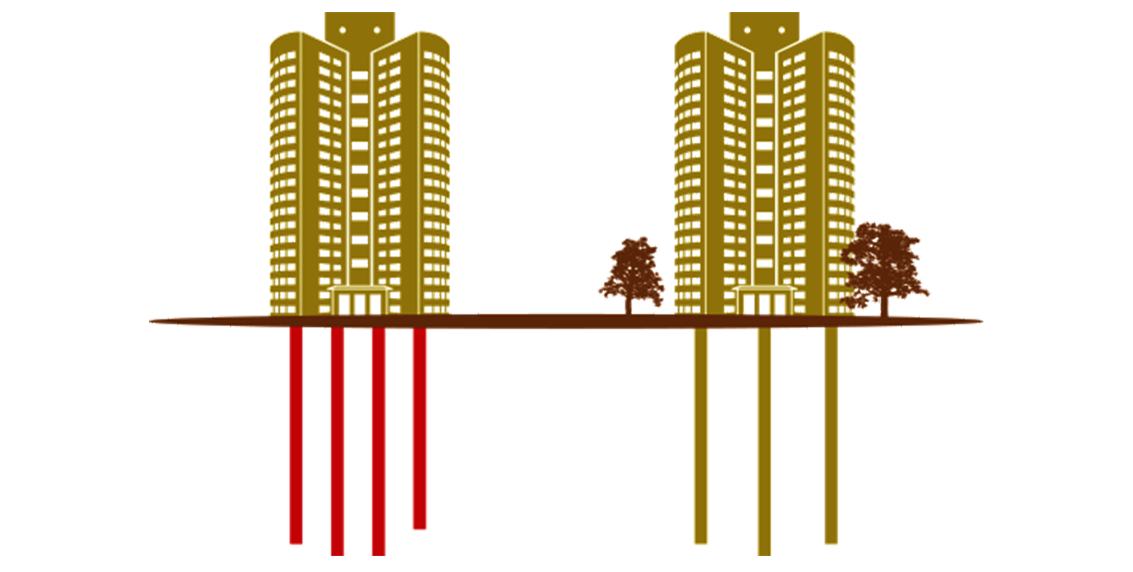

Aero Lite AAC Block is lightweight precast cellular concrete building material produced from a mixture of natural materials like sand, cement, lime, gypsum, and aeration agent. The product is widely used on both external and internal construction with added advantages of high resistance to fire, heat, and sound. As Aero Lite AAC Blocks are almost three times lighter than normal cement blocks or clay bricks, it significantly reduces a dead load of any structure making the structure safer all the time, especially during natural disasters like earthquakes.

Aero LITE AAC Block is a Nepal Quality Standard (NS-573) certified AAC Block and the company Aero Bricks is ISO 9001:2015 certified Company.

Highlighted Features of AEROLITE AAC Block are: -

- Lightweight

- Fire Resistant

- Thermal

Insulation

- Sound Resistant

- Safety

- Cost-Efficient

- Eco-Friendly

- Earthquake Resistant

- Easy

work-ability

- Low wastage

- Modern

Construction material

Read MoreLess

- Length: 600mm / 24inch

- Height: 200mm / 8inch

- Thickness: 150mm/6inch

- Product Code: 6 inch

-

Aero Lite AAC Block is lightweight precast cellular concrete building material produced from a mixture of natural materials like sand, cement, lime, gypsum, and aeration agent. The product is widely used on both external and internal construction with added advantages of high resistance to fire, heat, and sound. As Aero Lite AAC Blocks are almost three times lighter than normal cement blocks or clay bricks, it significantly reduces a dead load of any structure making the structure safer all the time, especially during natural disasters like earthquakes.

Aero LITE AAC Block is a Nepal Quality Standard (NS-573) certified AAC Block and the company Aero Bricks is ISO 9001:2015 certified Company.

Highlighted Features of AEROLITE AAC Block are: -

- Lightweight

- Fire Resistant

- Thermal

Insulation

- Sound Resistant

- Safety

- Cost-Efficient

- Eco-Friendly

- Earthquake Resistant

- Easy

work-ability

- Low wastage

- Modern

Construction material

Read MoreLess

- Length: 600mm / 24inch

- Height: 200mm / 8inch

- Thickness: 200mm/8inch

- Product Code: 8 inch

-

Aero Lite AAC Block is lightweight precast cellular concrete building material produced from a mixture of natural materials like sand, cement, lime, gypsum, and aeration agent. The product is widely used on both external and internal construction with added advantages of high resistance to fire, heat, and sound. As Aero Lite AAC Blocks are almost three times lighter than normal cement blocks or clay bricks, it significantly reduces a dead load of any structure making the structure safer all the time, especially during natural disasters like earthquakes.

Aero LITE AAC Block is a Nepal Quality Standard (NS-573) certified AAC Block and the company Aero Bricks is ISO 9001:2015 certified Company.

Highlighted Features of AEROLITE AAC Block are: -

- Lightweight

- Fire Resistant

- Thermal

Insulation

- Sound Resistant

- Safety

- Cost-Efficient

- Eco-Friendly

- Earthquake Resistant

- Easy

work-ability

- Low wastage

- Modern

Construction material

Read MoreLess

AERO BOND AAC Block Jointing Mortar is a cement based, self-curing & high strength pre-mixed mortar for jointing AAC blocks. AERO BOND AAC Block Jointing Mortar contains high graded OPC cement, graded sand & modified polymers. It is an ideal and perfect joining mortar specially made for AAC Blocks that makes the structure’s joints stronger, smoother, and uniform. It is a super bond technology to improve workability and durability.

Usage

- AERO BOND AAC BLOCK JOINTING MORTAR is the best product for laying & jointing masonry units like AAC Blocks.

- AERO BOND AAC BLOCK JOINTING MORTAR is the best product for laying & jointing masonry units like AAC Blocks.

Features & Benefits

- Easy to work

- Thin layer/ Light weight

- Reduce labour cost & time

- Reduce supervision cost

- Less mortar required

- Faster application

- Uniform

- Smooth finish to wall

- Self-curing

- Superior bonding

- High compressive strength

एरोप्लास्ट रेडिमिक्स प्लास्टर

एरोप्लास्ट रेडिमिक्स प्लास्टर उच्चकोटीको सिमेन्टमा ग्रेडेड बालुवाको मेसिन द्वारा मिश्रण गरिएको प्रि-मिक्स प्लास्टर मोर्टार हो । यो रेडिमिक्स प्लास्टरमा प्रयोग हुने बालुवाको आकार एकैनासको हुने हुँदा यसबाट प्लास्टर गरिएको भित्ता एकैनासको चिल्लो हुन्छ । ग्रेडीङ, गरिएको बालुवाको प्रयोगले माटोको मात्र सुन्य हुदा यसबाट भएको प्लास्टरको आयु लामो हुनुको साथै स्मुथ पनि हुन्छ । आवस्यक मात्रमा सिमेन्ट र बालुवा तथा पोलिमरको प्रयोगले गर्दा कामको गति बढ्नुको साथै आवश्यकता अनुसारको मात्रै परिमाणमा खरिद गरि प्रयोग गर्न सकिन्छ । त्यसैले निर्माण पछि थोरै थोरै सामाग्रीहरुको व्यवस्थापन गरिरहनु पर्दैन । एकै साइजको ग्रेडेड बालुवाको प्रयोग हुने हुँदा आफ्नो आवश्यकता अनुसारको मात्रै मोटाइको (पातलो/बाक्लो) प्लास्टर गर्न समेत सकिन्छ । प्रिमिक्स नै उपलब्ध हुँदा घोल्ने तथा छान्ने कार्य गर्नु पर्ने छैन त्यसैले कार्य गति र गुणस्तर दुवैमा ढुक्क हुन सकिन्छ । साथै सहरिकरण पछिको साँघुरो स्थानमा काम गर्न धेरै प्रकारका निर्माण सामग्री स्टक गर्ने गोदामको समस्या पनि हटाइदिन्छ । सानो-सानो काम गर्दा सबै प्रकारको निर्माण सामाग्री खोज्न लाग्ने समय र पैसाको समेत बचत गर्दछ ।

बिशेषताहरुः-

- माटोको मात्रा सुन्य भएको

- एकैनासको स्मुथ फिनिसिङ

- आबस्यकता अनुसार धैरै / थोरै खरिद गर्न मिल्ने

- असमान मिश्रण बाट हुने समस्याको समाधान

- समय / भण्डार स्थानको बचत

- पैसाको बचत

- छिटो र सजिलो

एरो टायल एडहेसिभ

एरो टायल एडहेसिभ टायल तथा मार्बल जोडाई गर्नको लागी तयार गारिएको बिशेष प्रकारको मोर्टार (एडहेसिभ) हो । उच्च कोटिको ओपिसि सिमेन्ट, ग्रेडेड बालुवा र बिशिष्टिकृत पोलिमरहरुको उत्कृष्ट संयोजन गरि तयार हुने यो एडहेसिभ परम्परागत मोर्टार भन्दा बिश्वसनिय एवं सजिलो रेडि-मिक्स टायल/मार्वल एडहेसिभ हो । भुँइ तथा भित्ता दुवै स्थानमा टायल लगाउनलाई मिल्नेगरि तयार गरिएको रेडि-मिक्स एडहेसिभ सजिलो र झन्झटमुक्त हुन्छ । मिलेको भुँइ तथा भित्ताहरुलाई थप प्लास्टर गरि सम्याउन नपर्नेगरि तयार गरिएको यो एडहेसिभले समय तथा पैसा दुबैको बचत गर्दछ । साना देखि ठुला र भित्रि बाहिरि जुनसुकै स्थानमा टायल/मार्वल जोडाईको लागी एरो टायल एडहेसिभ उपयुक्त हुन्छ । रेडि-मिक्स एडहेसिभलाई आवस्यकता अनुसार पानीमा मिसाई राम्रो सँग घोलेर प्रयोग गर्न सकिने भएकोले टायल तथा मार्वल जोडाई गर्न धरै प्रकारका सामग्रिहरुको खरिद, ढुवानि तथा भण्डारण गर्नु पर्ने समस्याको समाधान हुन्छ । भुँइ तथा भित्तामा वा धेरै ठुला टायल/मार्वलहरुको जोडाई गर्न फरक सेटिङ्ग समयको एडहेसिभ आवस्यक हुने हुनाले आफ्नो आवस्यकता अनुसारको टायल एडहेसिभको छनोट गर्ने सुबिधालाई मध्ये नजर गर्दै फरक बिशेषताका टायल/मार्वल एडहेसिभ उपलब्ध गराइएकोले सोहि अनुसारको प्राबिधिकहरुको सल्लाह अनुसारको सामाग्री छनोट गर्न अनुरोध गर्दछौँ ।

बिशेषताहरुः-

- सजिलो र सफा

- छिटो र छरितो

- पैसाको बचत

- बिश्वासिलो

- धेरै थरिको निर्माण सामग्रि भण्डारणबाट मुक्ति

एरो वाल पुट्टीः

एरो वाल पुट्टि एक white Cement मा आधारित पोलिमर तथा एडेटिभ्स भएको उत्पादन हो, जुन रफ प्लास्टरलाई स्मुथ बनाउन घरको भित्रि तथा बाहिरि भित्ताहरुमा प्रयोग गरि आकर्षक एवं मजबुत बनाउन प्रयोग गरिन्छ । एरो वाल पुट्टिको प्रयोगले घरका भित्ता हरुलाई राम्रो देखाउनुको साथै रङ्गको खपत पनि कम गर्दछ । सेतो रङ्गमा उपलब्ध हुने यो एरो वाल पुट्टिलाई सबै प्रकारका भित्री बाहिरी सिमेन्ट प्लास्टर, कंक्रीट आदिमा प्रयोग गर्न सकिन्छ ।

बिशेषताहरुः-

- भित्ताहरुमा एकसमान फिनिसिङ्ग प्रदान गर्दछ

- राम्रो कार्यक्षमता

- सेल्फ क्युरिङ्ग तथा पानी प्रतिरोधी

- ओस प्रतिरोधक

- उत्कृष्ट घर्षण प्रतिरोधक

- भित्तामा हुने फंगस हटाउने

- इमल्सन पेन्टमैत्रि

Red Clay Bricks Against AAC Blocks

| Indicator | Red Clay Bricks | AAC Blocks |

|---|---|---|

| Density (Normal Dry) | 1800-2000 Kg/m3 | 650-750 Kg/m3 |

| Compressive Strength (Dry) | 3.25 N/mm2 (MPa) | 3.25-4.25 N/mm2 (MPa) |

| Fire Resistant | 3 Hours (Max.) | 5 Hours (Max.) |

| Thermal Conductivity | 0.8 W/m2k | 0.16 W/m2k |

| Sound Reduction | 45 dB for 230mm thick wall | 50 dB for 200mm thick wall |

| Cost Benefit | None | Savings in Steel, Concrete & Manpower |

| Breakage: | 10-15% | Less than 5% |

| Size Variations | 5mm(+/-) | 1.5mm(+/-) |

Application

For any type of walls in residential, industrial, commercial, and institutional construction.

For special requirement applications like Aucostic and fire-related walls.

A major application of AAC products includes lightweight partition walls, protection of steel structures, and lintels

AAC Blocks offer a fast, convenient, and versatile for most walls.

FAQ

What are the basic features of AAC Blocks?

The basic features of AAC are Lightweight, sound insulation, thermal insulation, moisture resistant, fire resistant & earthquake resistant.

How much lighter is AAC than other wall masonry materials?

AAC Block weighs almost three times less than other building materials such as red bricks or concrete blocks.

What is the life of AAC?

The life of AAC is the same as other cement concrete i.e. 60+ years.

What are Aero Lite AAC blocks made of ?

Aero Lite AAC blocks are manufactured by using sand mixed with cement, lime, gypsum, water, and an aerating agent (Almina). The resultant building material comprises millions of tiny air pores.

When was AAC first developed?

AAC was developed in 1924 by a Swedish architect, who was looking for a lightweight building material with properties of good thermal insulation, sound resistance, solid structure, and ease of work.